Manufacturing: Nanomanufacturing

The Manufacturing of Nanodrug Carriers: from Concept to Practice

Nanodrug carriers have gained increased attention in the pharma industry since they were used in the fight against COVID-19. What are they, and how can regulations improve the manufacture of them?

By Setu Kasera at LEON-nanodrugs

The Groundwork for Making Nanodrug Carriers an Industrial Reality Was Laid Over the Past Couple of Decades

The important role that nanodrug carriers could play in global health challenges has been cemented by the recent worldwide administration of mRNA vaccines using lipid nanoparticles as drug delivery vehicles against COVID-19. The accelerated use of nanodrug carriers to remedy the pandemic was neither an overnight endeavour nor a serendipity. It was possible because it was informed by outcomes of research that were performed over decades in the broader interdisciplinary field of nanotechnology.1

A slow introduction to the topic in the 1950s followed by a higher pace of study of nanomaterials in the 1980s has laid the required foundation to build upon the future of nanomedicine. Driven by an initial attention on protection of drugs from degradation in the 1970s to their enhanced permeability and retention in the 1990s, the focus on the functions of nanodrug carriers has also been evolving. Over the last two decades, the potential to deliver drugs with high precision and efficiency – or ‘targeted’ delivery – has been in the spotlight, enabled by bioconjugate chemistry and engineering stimuli-responsive carriers. It is now well accepted that nano encapsulation can improve the solubility and stability of drugs, enhance their bioavailability and efficacy, as well as reduce their toxicity.

It must be noted that nanomedicine is not restricted to drug delivery systems and these materials themselves may become the active therapeutic ingredients and are increasingly used in medical diagnostics.

Technologies Used for Manufacturing Nanodrug Delivery Systems Need to Be Fit for Purpose

As the field of nanomedicine has progressed, the recurring challenge of scale up and Good Manufacturing Practice (GMP) quality aspects in manufacturing of nano formulations have become known widely. In recognition of these gaps, a few projects were initiated and supported by the European Commission (EC) under EU HORIZON 2020 to enable scale up of GMP manufacturing of nanomaterials: NANOFACTURING for solid core nano pharmaceuticals; NANOPILOT for polymer-based nanoparticles; and MACIVIVA to make virosome vaccines cold chain independent.

Bottom-up approaches, where nanoscale structures are built up from atoms or molecules, are more commonly applied in making nanodrug carriers than top-down approaches. In the latter case, bulk materials are broken down into smaller components through various techniques. Some methods that are used for manipulating nanomaterials in the lab (eg, nano extrusion) cannot be translated or multiplied readily for larger scale or high-volume GMP production.

Microfluidics and jet impingement technologies are currently at the forefront of manufacturing nanoparticles in industry. While well-studied systems like polymer particles or inorganic particles are becoming simpler to manufacture, more complex and bespoke systems like lipid-based nanoparticles comprising several components continue to enter the arena and nanomanufacturing technologies need to keep up with their pace. The challenge is even greater with tailored structures where no two nano systems are alike.

When producing systems that operate at such a small (nano) scale, the required precision is also immense because some systems can be very sensitive to small perturbations. Self-assembled nanostructures are held together by supramolecular forces, which are the result of a fine balance of kinetic and thermodynamic forces. Sufficient understanding of these forces that drive the formation of, or may perturb a given nanostructure, is not only necessary to engineer them (to achieve target functionality) but also plays an equally crucial role when selecting the right framework to manufacture them. For example, high shear forces can break up self-assembled hierarchical particles and rupture the payloads (eg, RNA), and methods that subject the particles to such harsh conditions (eg, high pressure homogenisation) are not suitable to manufacture them. Therefore, manufacturing technologies must be chosen depending on the nano system that is being manufactured.

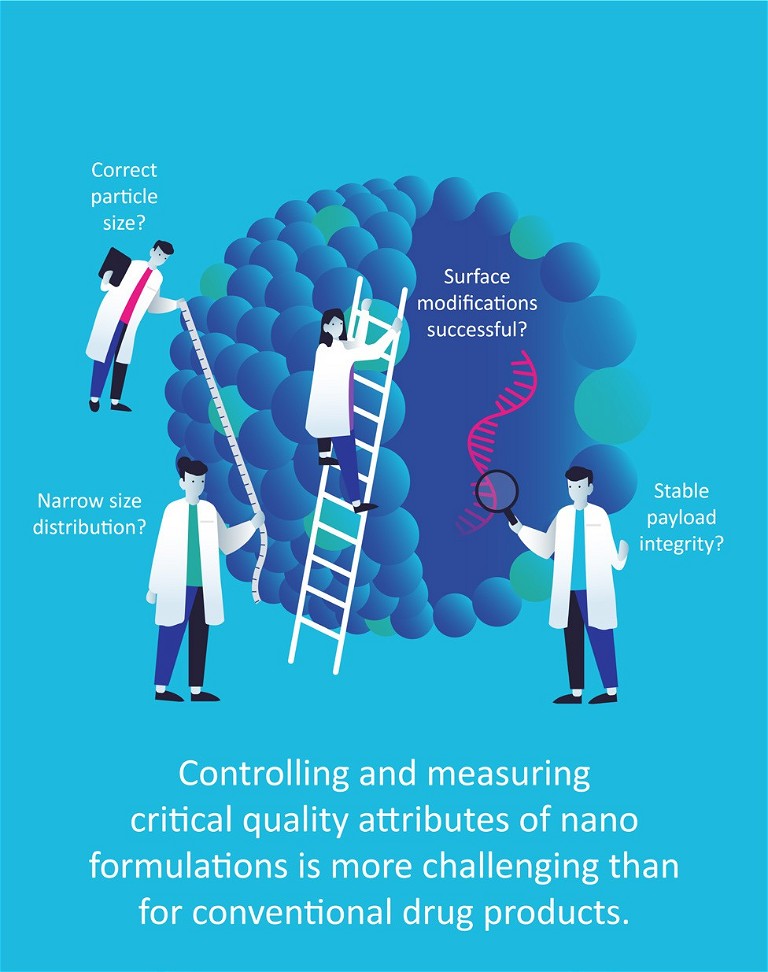

Figure 1: Challenges to nano formulations – controlling and measuring critical quality attributes

The Sector is Growing with New Entrants and the Translation Gap is Beginning to Fill

It is well-recognised in the community that the methods used for making lipid nanoparticles to supply COVID vaccines were only the beginning on the road to sustainable long-term solutions.2 Manufacturing aspects ranging from batch-to-batch particle variability, consistency of drug encapsulation efficiency, production volume, effective material turnover and stability of the particles still show considerable potential for improvement. The upside is that the emergence of the gaps in nanomanufacturing for pharmaceuticals became obvious and provided the much-needed impetus to develop the right solutions. This recognition is evident from the recently increased activity in this sector, both in terms of new market entrants and governmental support.

Quality Assessment of Nano Formulations is More Complex Than for Conventional Drug Products

Successful translation of the nano formulated products needs to meet the same safety, efficacy and pharmaceutical quality criteria as conventional drug products. The assessment of the quality of nano formulations, however, requires characterisation of several additional physico-chemical attributes than is routine for conventional drug products. For example, a typical drug product requires evaluation of identity, strength, potency, stability, impurities, bacterial endotoxins and bioburden of the chemical ingredients. In case of nano formulations, the particle size, size distribution, surface charge, encapsulation efficiency, drug release profile, physical structure, chemical and size stability also need to be measured in addition. Ensuring these critical quality attributes is of outmost important for these entities because if these nanostructures are not precise, they may alter or lose their functionality.

Measurement of these properties also requires special analytical instruments and expertise. Depending on manufacturing conditions, the stability of some nanoparticle systems can exhibit very high temporal sensitivity (eg, <30 minutes) making them less amenable to standard in-process or batch testing protocols. Therefore, real-time release solutions are a more suitable route to consider for GMP nanomanufacturing technologies.

In general, implementing in-line process analytical technology tools are expected to improve process understanding, increase efficiency and reduce waste, leading to products with better quality at reduced costs.3 Although a range of sensor choices are becoming available for monitoring critical process parameters (eg, flow rates), in-line sensors that are suitable for measuring nanoparticle quality attributes for GMP production have yet to cover the full scope of desired parameters. There remains a need for further development of analytical systems in the nano regime that will be suitable for widespread and easy industrial applicability.

Regulatory Landscape for Nanomanufacturing for Pharmaceuticals is Progressing at a Slow But Steady Pace

The developments in the ability to assure quality go hand-in-hand with the state of the regulatory landscape, which continues to be refined and harmonised. The FDA has been issuing guidance documents as a part of the implementation of the Nanotechnology Task Force Report (2007), which includes the Final Guidance Documents for Industry on Liposome Drug Products, (2018) and Drug Products, Including Biological Products, that Contain Nanomaterials, (2022).

Despite joint efforts across regulatory bodies, metrology institutes and standard authorities, the progress towards standardising characterisation approaches and harmonisation has been slow. The pace is affected by the inherent versatility and complexity of specific nanomaterials to enable determination of different aspects of drug properties, eg, drug loading (free vs encapsulated drug), particle stability in biological media, surface properties and interactions with the biological environment.4 In order to address this, the European Medicines Agency (EMA) has published a strategic reflection on Regulatory Science to 2025, where the Agency proposes to share knowledge and harmonise regulatory practices.5 This includes developing and standardising new testing methods related to the quality and safety assessment of nanomedicines.

A Prevention Approach is Necessary to Address High Susceptibility of Nanoparticles to Contamination

In conventional drug products manufacturing, it may be possible to eliminate contaminants at the penultimate and/or ultimate steps followed by terminal sterile filtration. This may not necessarily be the case for nanoparticle formulations. Contamination with foreign matter (biological or non-biological) at any stage post particle-formation can compromise colloidal integrity and stability, which can result in batch losses or impaired pharmacological function. For example, a terminal filtration step (using a 0.22μm membrane), which is commonly used for parenteral products, may not always be a technically viable option for nano systems as the filter may also trap the particles. In addition, formulations can get contaminated with endotoxins (lipopolysaccharides, LPS) during production or handling, and identifying a suitable method to remove them is generally not straightforward and a case-by-case approach must be taken. In case of nano formulations, there is the added complexity that the method should not influence the physico-chemical properties of the nanoparticles.6 Therefore, a key consideration in GMP nanoparticles production is to maintain pristine materials throughout the chain of unit operations, if possible.

Considering this, the latest manufacturing systems are increasingly leaning towards using single-use components and closed aseptic designs to maintain sterility starting upstream in the particle production stage of the process. This approach is aligned with the contamination control strategy recommended in the recently released guideline EU GMP Annex I: Manufacturing of Sterile Medicinal Products, (Aug 2022).7 Such strategies are expected to move GMP nanomanufacturing processes away from highly classified cleanroom requirements while reducing chances of contamination significantly, increasing speed and efficiency, reducing material loss and decreasing operational costs, as well as protecting workers from exposure to potentially harmful agents. In addition, automated ‘plug-and-play’ systems are nearly becoming an elementary feature of nanomanufacturing systems, which are aimed at minimising the need for manual operations and reducing human errors, enhancing the ease-of-use to simplify training, lowering user knowledge requirements and drawing in customers more easily.

Trends and Outlook for GMP Nanomanufacturing

While the long-standing goal of achieving the ‘magic bullet’ through the promise of targeted nanodrug carrier systems appears to be in sight, we are not quite there yet.

Synergistic convergence of efforts across multiple disciplines continue to improve our understanding of the underlying principles of nano structures and enabling better control over manufacturing them. Progress is being made across the entire value chain to eliminate product susceptibilities. This includes aseptic upstream operations for production of nanoparticle intermediates, downstream purification and packaging. In addition, efforts are being put into solving logistic complexities, such as cold chain requirements.

The industry is only at the dawn of nanomanufacturing for the life sciences and we can look forward to several innovative solutions emerging from ongoing efforts in the near future.

References

References

- Couvreur P (2019), ‘Nanomedicine: From where are we coming and where are we going?’, Journal of Controlled Release 311–312, 319-321

- Tinari S (2021), ‘The EMA covid-19 data leak, and what it tells us about mRNA instability’, the BMJ 372, 627

- Mo J and Severson K et al (2017), ‘Opportunities and challenges of real-time release testing in biopharmaceutical manufacturing’, Biotechnology and Bioengineering 114(11), 2445-2456

- Germain M et al (2020), ‘Delivering the power of nanomedicine to patients today’, Journal of Controlled Release 326, 164-171

- European Medicines Agency (2020), ‘EMA Regulatory Science to 2025 - Strategic Reflection’

- Li Y et al (2016), ‘Endotoxin contamination: a key element in the interpretation of nanosafety studies’, Nanomedicine 11(3), 269-287

- European Commission (2022), ‘Annex 1: Manufacture of Sterile Medicinal Products (The Rules Governing Medicinal Products in the European Union Volume 4 EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use)’

Dr Setu Kasera serves as chief scientific officer at LEON-nanodrugs GmbH. With nearly a decade of hands-on experience in nanotechnology, she is directing research at LEON and is responsible for managing product development and data generation as well as strategic collaborations. She received her PhD in chemistry from the University of Cambridge, UK, followed by positions in research and business strategy in the biotech industry, with a focus on nanotechnology, drug development, CMC and science management.